The Exolon Group’s Med range has a new addition: Inspria® Med, made of Eastman Tritan™ copolyester. The solid sheets for medical applications complement the Exolon® Med and Vivak® Med sheet materials. “By expanding our range of sheets for medical requirements, we can now cover a wide range of applications with our material,” says Jens Becker, CEO of Exolon Group. Applications for Exolon Group’s Med product family range from dental splints and rigid medical packaging to containers and trays for medical devices.

The new addition can be thermoformed with extreme draw ratios and high impression reproducibility, making it suitable for the production of dental splints, among other applications. The clear transparent plates made of copolyester are also made for strong temperature differences: they can withstand temperatures of up to 90 °C and are easy to process. The material is suitable for various sterilization methods, including gamma radiation and ethylene oxide.

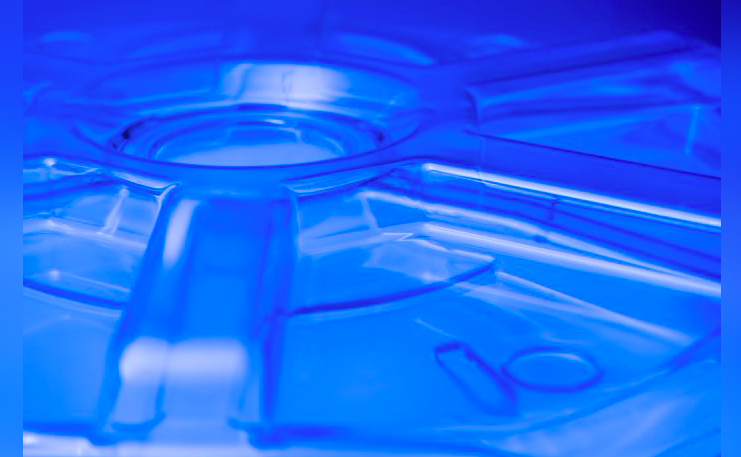

Vivak® Med, made from Eastman Eastar 6763, is ideal for thermoformed containers and trays for medical devices and skin contact applications, such as prostheses. The material can be rapidly thermoformed with low energy consumption, short production cycles, extreme elongation levels and accurate reproduction of the mold surface without pre-drying.

The polycarbonate product is highly impact resistant and suitable for rigid packaging and transparent protective devices on medical devices. Exolon® Med sheets can be easily thermoformed, cold bent and machined. They can withstand temperatures up to 120 °C.

Safe and traceable to the raw material

All Med-Range products are made from 100% virgin material that meets the requirements of ISO 10993 for the biological evaluation of medical devices. The plates are produced according to the rules of good manufacturing practice (GMP). The manufacturing process is subject to constant control by a quality management system that complies with the ISO 9001:2015 standard. Processors can thus trace the sheet material down to the raw material — an important basis for further documentation of future end products.