Energy efficiency at a new level

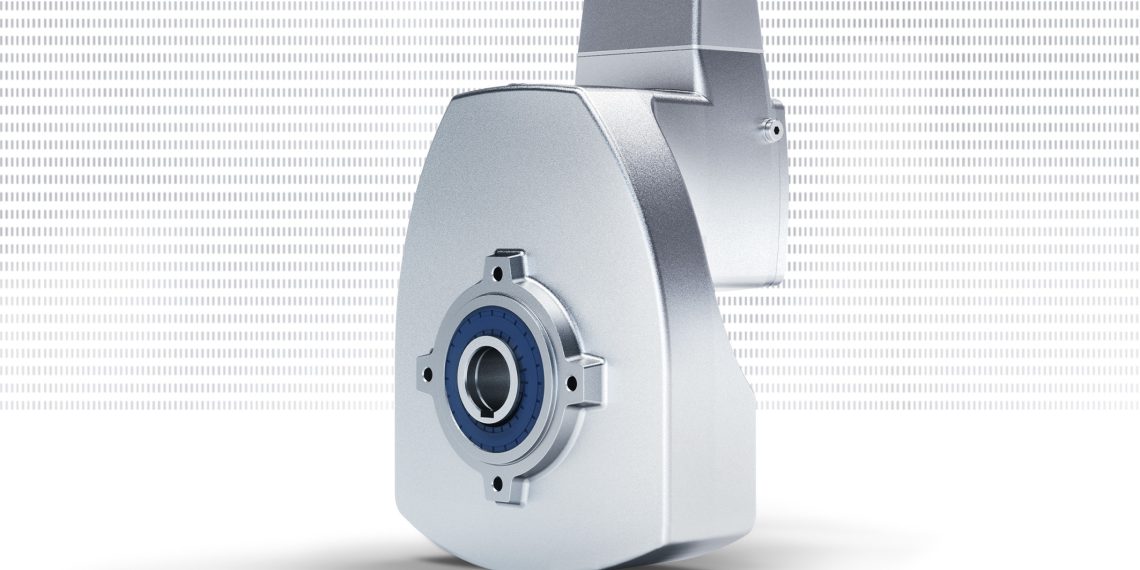

With the IE5+ synchronous motor, Nord has already succeeded in significantly reducing losses once again compared to the current IE4 series. The patent-pending DuoDrive goes one step further and sets new standards in terms of performance, installation space and variant reduction. At up to 92%, it offers one of the highest efficiencies of any gearmotor in this power class on the market and achieves very high system efficiency even in part-load operation. This makes it future-proof and a true cost reducer. This was achieved by fully integrating the IE5+ synchronous motor into a single-stage helical gear unit — a completely new approach to gearmotor design.

Smart frequency inverters for IIoT applications

In the field of frequency inverters, the company is presenting two new products at SPS: the Nordac PRO SK 500P control cabinet inverter with an extended power range of up to 22 kW and the Nordac ON decentralized inverter for small power ranges of up to 1.0 kW. A characteristic feature is the integrated multi-protocol Ethernet interface. Whether ProfiNET, EtherNET IP or EtherCAT — the desired protocol can be easily set by parameter. This results in a variant reduction with additional space and cost advantages, because no Ethernet add-on module is required. Perfect for use in IIoT environments. Two variants are available: While the Nordac ON was designed for operation with asynchronous motors, the Nordac ON+ is intended for combination with synchronous motors and complements the high-efficiency portfolio around the new IE5+ motor generation.

Digitization

All frequency inverters feature a powerful PLC for drive-related functions. This can process the data from connected sensors and actuators, initiate sequence controls autonomously, and transmit the drive and application data to the control station, networked components, or an existing cloud. This enables continuous condition monitoring and thus lays the foundation for predictive maintenance concepts and optimized plant dimensioning.

Experienced drive partner for logistics

The new inverter has been specially adapted to the target applications of horizontal conveyor technology. As a long-standing and experienced logistics partner, the Group knows the needs of the industry inside out and supplies scalable drive solutions for all subsectors. In doing so, the company pursues a comprehensive TCO approach that creates an optimal compromise between investment, operating and maintenance costs. The drive solutions are characterized by high operational reliability, cost-effectiveness and service life, and combine the ideal combination of variant reduction and energy efficiency. A reliable flow of goods is thus guaranteed.