Digitalisation of production is also fundamentally changing the field of maintenance and repair. Smart networking of plant and machinery enables the recording and evaluation of large amounts of performance data and therefore continuous status monitoring and predictive maintenance. Current developments and the latest innovations are displayed by the industry every two years at Underhåll in Sweden, Northern Europe’s leading specialist exhibition for industrial maintenance and repairs. Nord Drivesystems will also be exhibiting and, from 13 to 16 March 2018 in Gothenburg, it will be presenting intelligent drive units, smart solutions for networked production, as well as innovative technologies and new products.

In an application test area, the drive specialist from Bargteheide is demonstrating the drive unit of the future as well as the options for Cloud links and for Industry 4.0. Nord drive units can be networked, operate autonomously and can be scalable with regard to function and performance. Thanks to frequency inverters with integrated PLCs they continuously record the drive and application data, evaluate all of the available sensor and actuator data, take over tasks independently and provide optimised diagnostic facilities. The drive units communicate their status data via the control system or directly into the secure Cloud. From there, they are available all over the world for evaluation and analysis. Thus, the entire system of Nord drives can be monitored. This enables Predictive Maintenance, an increase in plant availability, reduction of maintenance and repair costs as well as optimised coordination of servicing. Future-oriented optimisation can also be carried out thanks to status monitoring.

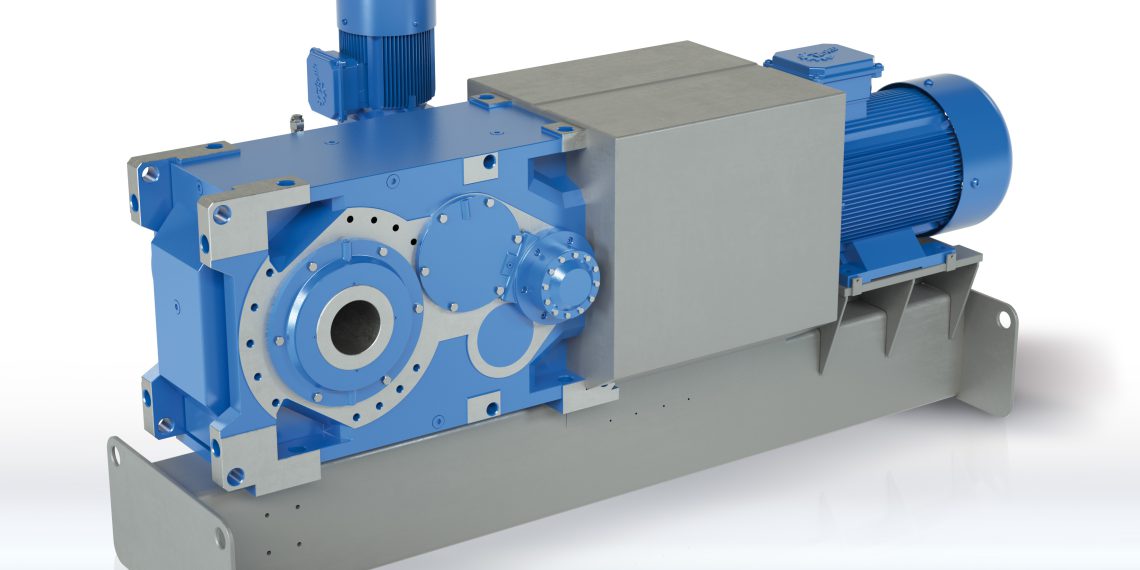

In addition, in Sweden Nord will present product innovations as well as efficient solutions for variant and cost optimisation. Nord Drivesystems has extended its Maxxdrive industrial gear unit series: Two additional sizes (rated torques from 15 kNm and 20 kNm) as well as extruder flanges supplement the modular series and provide new solutions for heavy duty applications. For demanding conditions NSD Tuph has been developed – a surface treatment which makes aluminium geared motors as resistant as stainless steel products and which is considerably more effective than anti-corrosion painting. Products treated with NSD Tuph are easy to clean and resistant to acids, alkalis and corrosion. One option for variant and cost optimisation is Logidrive. The standardised geared motor variants for intralogistics and airport applications are highly efficient. Thanks to Plug & Play technology they are extremely maintenance-friendly and result in a considerable reduction of spare part stocks.

At Underhåll, Nord can be found in Hall 11, on stand B06.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more