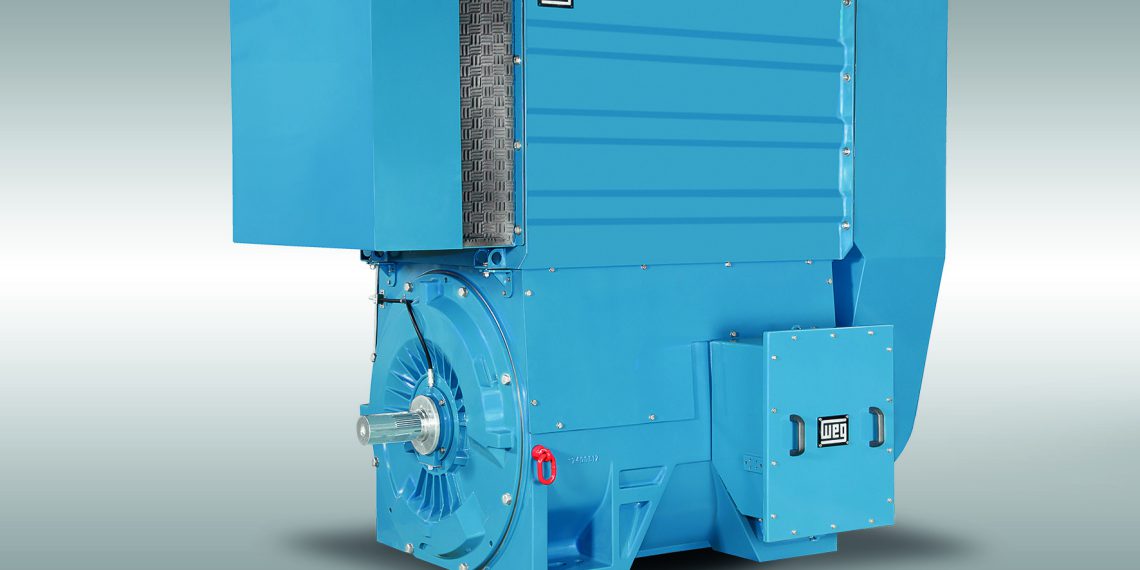

WEG has extended its W60 motor series, which now covers a power range of 500–16,000 kW at frequencies of 50 or 60 Hz. The three-phase induction motors are designed for the 2,300–13,800 V voltage range and are available with frame sizes from IEC 450 to IEC 1000 (NEMA 7000 to 1600). Designed for industrial applications such as compressors, pumps and fans, the W60 line provides high performance and reliability even under the most difficult operating conditions. The W60 is used mainly in the oil and gas sector, in mining, for electrical generation in power plants, in cement production, as well as in water and waste water applications.

“The W60 motors have been very well received by the market since being introduced in 2014,” says Andreas Schulte Mesum, Director European High Voltage Solutions at WEG in Germany. “WEG has designed all the motors in the expanded W60 line with the help of the latest software in order to achieve the highest reliability combined with long service life. The result is a compact, robust design which permits operation even in the toughest environments. It also boasts very low noise and vibration levels whilst also being suitable for high-speed applications. With the powerful standard W60 series motors WEG supplies comprehensive and competitive solutions in the medium and high voltage range.”

Robust, light, space-saving and efficient

Due to its optimised design, the W60 series motors are not only more compact, but also lighter than their predecessors. The compact dimensions offer a significant advantage: the W60 motors take up to 50 % less installation space than comparable motors. This makes them one of the most compact modular motors of this type on the market. The rugged design with high-quality housing and end shield are made of grey cast iron up to the IEC 560 standard. Sizes above IEC 560 feature a steel housing. A specially designed motor shaft prevents critical flexural vibrations at rated speeds – as well as below the rated speed in the case of two-pole motors – and ensures particularly low vibration levels. As a result, the W60 motors are also suitable for applications with frequency converters or heavy vibration loads. Thanks to the high-quality rotor and stator lamination, low-loss fans and optimised heat exchangers, the W60 series motors achieve unusually high efficiency and power density (output power relative to the weight). As a result, standard W60 series industrial motors are among the most efficient of their type on the market. What’s more theW60 motors are engineered for continuous use, horizontal mounting configuration and are easy to install and commission. They are also ideal for use with medium-voltage frequency inverters as standard, with no speed restrictions due to critical vibration speeds. The three-phase induction motors are designed for protection classes IP24W to IP55 and are suitable for safe or hazardous areas (Safe or Hazardous: Ex‑n, Ex‑t, Class I Div. 2, Class II Div. 2).

Flexible and modular

The W60 series benefits users in the form of maximum flexibility, as the 2 to 12-pole motors are available in three configurations: open and self-ventilated (IC01, WP-II), closed with air/air heat exchanger (IC611, TEAAC) and with air/water heat exchanger (IC81, TEWAC). The two-pole motors up to size IEC 560 are equipped with ball bearings, and are optionally available with sleeve bearings. Sleeve bearings are available as standard for larger two- and four-pole motors, but also for the complete W60 series if required. Thanks to the modular design, users can customise the motor to suit their specific application by means of optional expansion components such as differential pressure switches (air-cooled), leak detector (water-cooled), automatic lubrication system (anti-friction bearings) or rotary encoder.