From May 4 to 9 at IFFA, Frankfurt (Germany) Gea will present their process expertise, technology leadership and customer-centric services for the meat industry under the motto ‘Excellence at Every Stage’. The technology leader will be exhibiting at booth D06 in hall 8 and focus on four main application areas that link back to this year’s theme, specifically: tempura-coated and homestyle coated products, the art of bacon making and sausage. Key processing and packaging exhibits will be linked to the four application areas, demonstrating the benefits of automation; optimal process control; as well as the efficient use of resources, energy and labor in meat manufacturing. Excellence at every stage is more than just a theme; it is a promise found at the core of Gea’s food processing and packaging business, which encompasses our technology, service and our people, who strive to deliver maximum performance at each stage of the journey from ingredients to a delicious food product.

Technology in focus

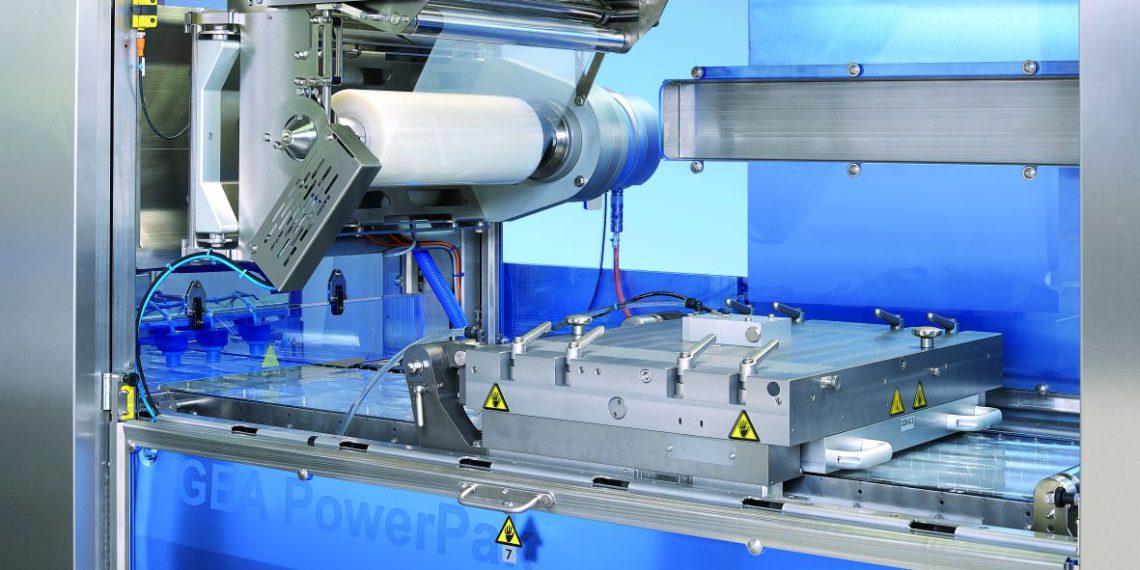

Key innovations from the equipment side include the new MultiJector 2mm, the new multi-purpose brine injector with flexible needles; the new thermoforming packaging machine PowerPak Plus, the first inline smoking application SuperHeatSmoke on Gea CookStar and the CutMaster Duo, a powerful raw sausage cutter with two independent drives, each with variable speed control. Additionally, attendees will get to see the new decanter series, Gea ecoforce for processing high quality animal by-products and Gea’s inline freezer control system Callifreeze.

IFFA attendees visiting the Gea booth will have the opportunity to engage with the company’s technology at varying levels via live demonstrations of innovative food products made on Gea equipment, through VR tours and interactive presentations.

Uniform injection thanks to unique 2mm OptiFlex needles

The new brine injection system in the Gea MultiJector 2mm is specifically dedicated to precise bacon and poultry processing, for 700 mm wide lines. The system features two millimeter OptiFlex needles, to date only available from Gea, which deliver a tight injection pattern, allowing for exceptional injection accuracy, product quality and consistency. The new equipment is seamlessly integrated within the Gea SuperChill brine chiller and the Gea MultiShaker, which removes excess brine, closes needle marks and activates proteins, ultimately resulting in low standard deviation during production and thus increasing quality, yield and profit.

Gea at the IFFA 2019: Hall 8, Stand D06