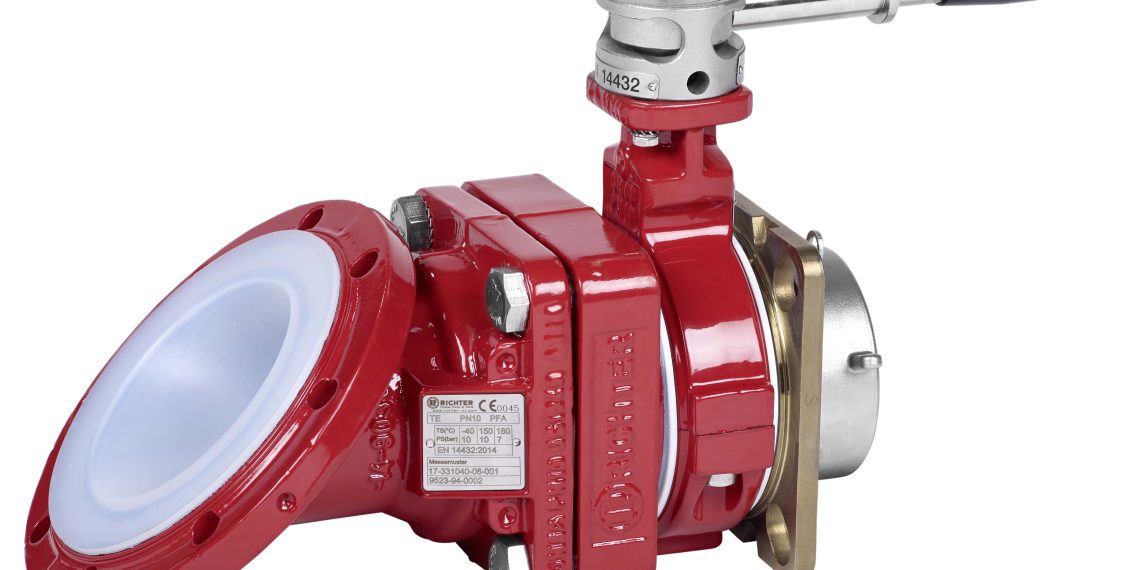

Richter Chemie-Technik GmbH introduces the first PFA lined Tank bottom valve system. To increase safety and efficiency of mobile tank operation, Richter has developed a new universal corrosion-resistant bottom valve, associated butterfly valve and the first PFA-lined 3” BSP flange.

Universally corrosion resistant PFA lining allows maximum flexibility in various applications. The new design reduces potential leakage risk. It also eliminates high costs from damage to the lining, broken locking mechanisms or flaking off of thin Halar coatings, while increasing product lifetime.

The bottom valve TE / F combines the proven technology of Richter ball valve series KN / KNA and the Richter butterfly valve NKS in numerous worldwide applications in chemical plants. It enables the safe transport of highly corrosive and environmentally hazardous liquids. Both series are already recognized for their reliability, ease of maintenance and long service life in the chemical industry. The ranges have been consistently adapted to the extreme requirements and are based on more than 30 years of experience with lined valves for use in various areas of the chemical industry.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more