Especially designed to meet high pressure and extreme temperature demands, with the new developed series 190 Arca Regler completes the product range of control and shut-off valves for the steam turbine periphery, but also for various other applications.

Due to the rapidly increasing requirements especially in power plant technology, valves in such service will suffer high stress – inappropriate design or material selection could lead to early failure of the valve with impact to the availability of the whole plant.

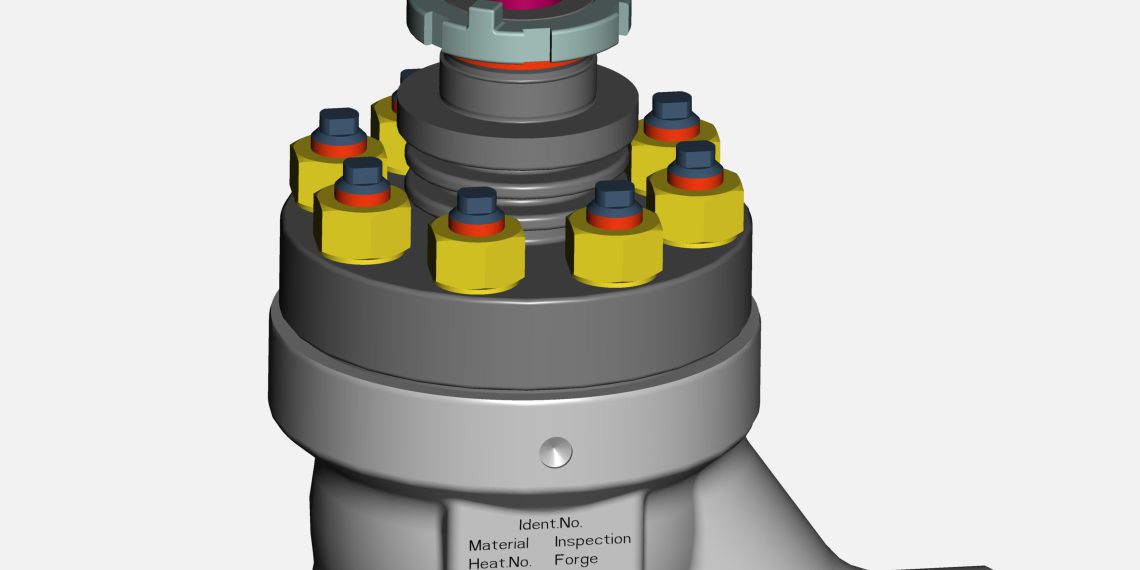

For this reason, when designing the new series 190, as a matter of principle the pressure containing parts (valve housing and bonnet) have been selected to be dye-forged parts. This manufacturing process guarantees a very homogeneous material structure without any discontinuities. Such microscopic defects, which are very difficult to prevent and to evaluate especially on cast materials, may lead to incipient cracks under hard mechanical or thermal alternating load and with this to early failure of the valve.

Additionally, most advanced CDF-technology was used to optimize the design of the valve body to avoid tension peaks resulting from sudden temperature changes.

The valves are delivered with butt weld ends per EN 12627 or ASME B16.25; with pipe outside diameter from 33,7 mm up to maximum 76,1 mm. Optionally, socket weld end or threaded connections are available.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more