When a UK-based electricity producer was experiencing frequent breakdowns due to bearing failures in two industrial fan units, the plant requested the services of NSK to propose and implement a suitable solution. After performing an application review as part of NSK´s AIP (Added Value Programme), a change of bearing and fixing arrangement led to significant cost savings.

The two direct-drive overhung fans, which are supported by spherical roller bearings in plummer blocks, operate 24/7. As primary total air fans, their role is to feed air to the boiler at a rate of 8 m³/second with an output pressure of 13 kPa. However, the bearings in each unit were failing every three months on average, a situation that would take three engineers 10 hours to remedy each time, incurring high costs per breakdown.

The long time and high cost of replacement was largely due to the size of the task. Each fan is around 3.5 m in diameter and attached to the end of a 2 m long, 135 mm diameter shaft. Shaft rotation is 1487 rpm, powered by a directly coupled 350 kW electric motor.

NSK´s comprehensive application review included a failed bearing examination from the drive and non-drive end bearings. A number of issues, including fretting corrosion, were noted to the external diameter of the outer ring. It was also clear that both bearings exhibited a raceway which had supported an axial load; evident from a wider and more pronounced running band. This is unusual as the fan configuration had a fixed and free-end arrangement — to allow for shaft expansion from operating temperatures — thus the free end should only support a radial load.

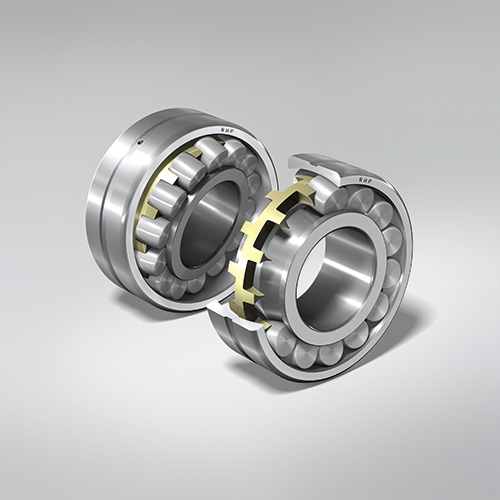

As the free end bearing at the energy plant exhibited axial loading, the company was able to attribute the root cause of the ongoing failures to incorrect bearing arrangement. High-capacity Spherical Roller Bearings within SNN Plummer Blocks were therefore recommended, along with correcting the fixing arrangement. The Spherical Roller Bearings use state-of-the-art materials that make them suitable for high speeds and loads. Offering special ring tolerances to withstand vibration, shock loads and misalignment, the bearings are heat stabilised up to 200°C. Furthermore, high-capacity Spherical Roller Bearings were the preferred choice as the internal design is more reliable for direct-coupled overhung industrial fan units, thanks largely to inner ring ribs that provide better roller guidance.

Biogas technologies for production of biomethane

The untapped feedstock potential for biomethane production in Spain is very large as the country has a very strong food...

Read more