ABB’s new modular automation system provides the flexibility that is needed through a building block approach that can be scaled up or down depending on the production demand.

The new modular automation system is ideal for pharmaceutical plants, biotech manufacturers, fine chemical factories and food and beverage industries. It is the first time that the company offers a solution based on the modular automation concept to automate and orchestrate intelligent modules tailored to the plant’s manufacturing needs. The new solution also offers seamless integration with many existing systems, offering less downtime during implementation. The result is less support and troubleshooting and an improvement of run-time within the plant.

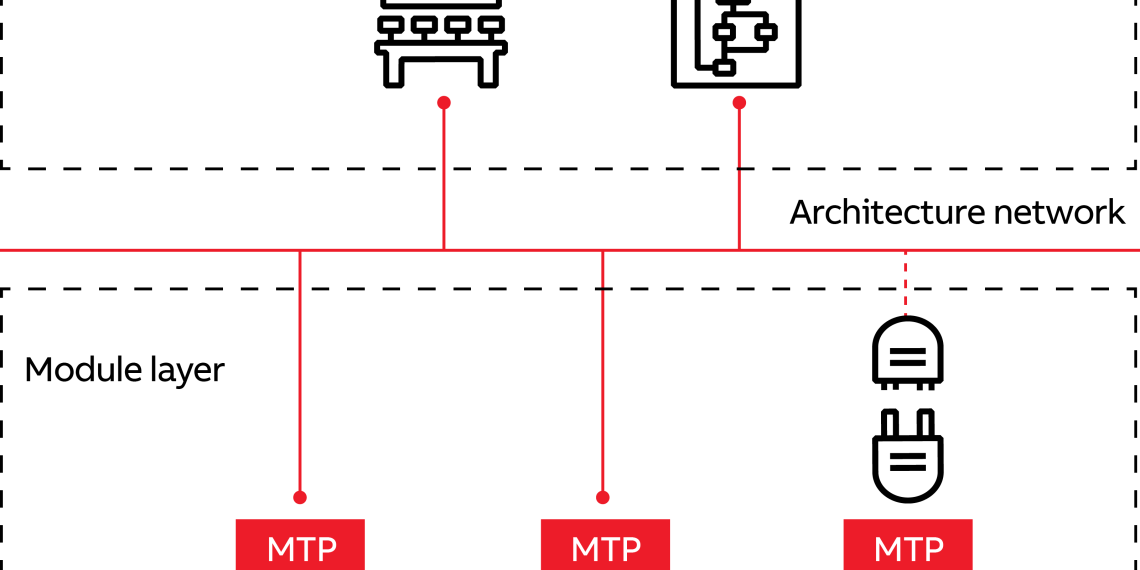

The orchestration layer is a combination of operations and supervisory control of the modules. Ability System 800xA operates the process and orchestrates the intelligent modules. The system also enables fast and flexible integration of the modules.

The System 800xA operations HMI functionality is enabled for operator effectiveness which allows for quick and intuitive decisions based on rapid access to data. Batch management applications can be used to improve batch production. Efficient alarm management and a high capacity and secure data storage for processing information is also available.

An open architecture backbone links the orchestration layer to the module layer with communication via OPC UA. Modular enabled automation reduces cost, risk and schedule by eliminating the non-standard interfaces. Integrating an intelligent module into the orchestration system is a matter of hours compared to days for a traditional package unit and skid integration.

ELGi’s EG Series Air Compressors Deliver Energy

Alucosur, one of the leading Spanish surface treatment companies, fulfilled their need for high-quality and energy-efficient compressed air with EG...

Read more